| Light Sport Aircraft · Safety Directives and Service Advisories | |

| Please check back here often to ensure you have the latest information. Send any questions, comments, or requests for product information to ultrikes@northwing.com Safety Directives are mandatory changes to your aircraft, and the aircraft is grounded until it is fixed per the instructions of the manufacturer. Service Advisories are recommendations that are advising the customer of something that was brought to our attention. The customer is advised to check out their aircraft, and take care of the problem if they find something and notify us. Not mandatory unless you find the same issue. |

|

|

Click here to download our Continued Airworthiness Safety Reporting Form. If you have any incidents of any flaws with North Wing aircraft, please use this form to document the details of the incident and send to us. Thanks! |

|

|

All North Wing Trike Wings are GROUNDED ...until wing-owner checks their Tip-Cap Webbing and Size, per the notes in Safety Directive 501 Click here to print Safety Directive 501 |

|

|

Scout XC Apache · Scout XC Navajo · Sport X2 Apache · Sport X2 Navajo Please note that the previously published fuel capacity of our new Fuel Tank was in error. The Fuel Tank on our 2-place trikes has a capacity of 13.5 Gallons, with 12.75 gallons available for use. |

|

|

Advisory #: SA-101 Part: Fuel Drain Valve Ref: leaking fuel Number of Incidents: 1 We have had one incident where as the Fuel Drain Valve (located under the fuel tank) leaked fuel over night. The cause may have been a faulty o-ring, the fuel additive compromised the o-ring or it did not reset after the fuel was checked. There is no reason to change your check valve at this time. We are just advising you to watch the valve for leaks after every time you check for water in the fuel. |

|

|

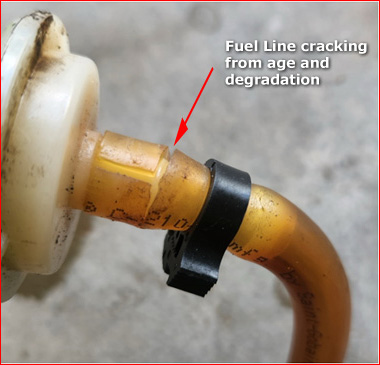

Advisory #: SA-102 Part: Fuel Line Ref: degrading fuel line Number of Incidents: 3 Warning: Transparent Fuel Lines sometimes crack from age and degradation. Please inspect your fuel line for cracks. The cracks look like a shattered-glass pattern. The fuel line, when twisted, just fell apart. Until then, it stayed intact. We believe that old fuel was the cause. If you are using transparent fuel lines, be sure to check them often for signs of failure. It has been found that they can shows signs of distress and failure before the end of their expected life-span. North Wing recommends using the quality fuel lines from Gates when you are replacing fuel lines.   |

|

|

Advisory #: SA-103 Part: Fuel Line Ref: fuel line abrasion Number of Incidents: 1 One incident of the fuel line going to each carburetor rubbing on the hose clamp for the equalization line was reported on a 912 with 135 hrs. These lines come from the fuel splitter after the fuel pump.  They are located on top the engine and branch to each carburetor. They were tightly secured to the equalization tube, but the engine vibrations still caused the fuel line to rub against the equalization line hose clamp causing considerable wear. If not corrected, it was estimated the line would begin to leak fuel over the engine during flight after about 250 hours. They are located on top the engine and branch to each carburetor. They were tightly secured to the equalization tube, but the engine vibrations still caused the fuel line to rub against the equalization line hose clamp causing considerable wear. If not corrected, it was estimated the line would begin to leak fuel over the engine during flight after about 250 hours.To prevent this from re-occurring, a shield made of another hose was wire tied between the fuel line and the equalization tube to prevent contact with the hose clamp (See picture). This had to be done on the fuel line to each carburetor. It is suggested all 912 owners check for wear at this point. |

|

|

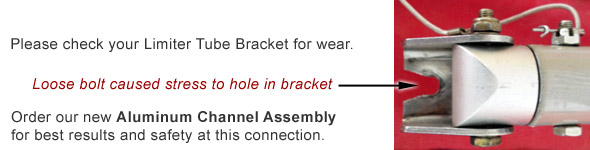

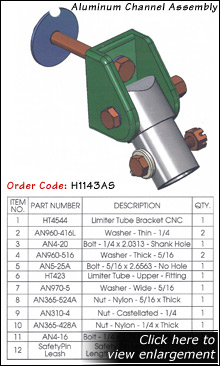

Advisory #: SA-105 Part: #H1129 Ref: loose bolt can cause hole abrasion Number of Incidents: 1  One incident of the Limiter Tube Bracket (#H1129) failed at the hole. The trike had over 900 hours.  We have received reports from 8 other trikes that were inspected for this, ranging from 200 hours to 1000 hours, and from production models 2004 to 2011. We found one bracket with cracks around the hole. It has been determined that this was caused by the bolt being very loose, and the bracket being able to move, causing impact force on the hole. We have received reports from 8 other trikes that were inspected for this, ranging from 200 hours to 1000 hours, and from production models 2004 to 2011. We found one bracket with cracks around the hole. It has been determined that this was caused by the bolt being very loose, and the bracket being able to move, causing impact force on the hole.• Make sure the back bracket is setting flat against the tube. • Make sure the nut is tight, so the bracket cannot be turned without 15 to 20 pounds of force. Recommended Solution: At this time, we recommend that both limiter tube brackets being replaced every 300 hours. Part #H1129 View Parts List We recommend replacing the bolt and limiter tube fitting with our new complete assembly - available for $55.00. Order Code: H1143AS View Parts List & Diagram Click here to send an email message to North Wing to request the new aluminum Channel Assembly. |

|

|

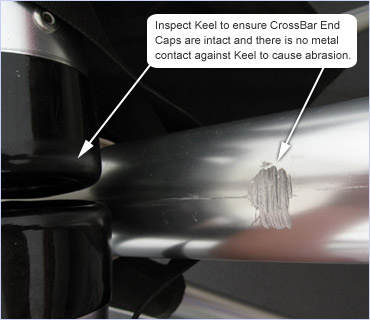

Advisory #: SA-106 Part: Airframe Keel Ref: CrossBar abrasion Number of Incidents: 1  One incident of the Keel receiving abrasions from the CrossBar, when the protective end-cap had come off, was reported. We advise pilots to inspect the Keel where the CrossBar sets above it, to ensure there is no metal-to-metal contact that results if the protective end-caps of the CrossBar become dislodged, for whatever reason. One incident of the Keel receiving abrasions from the CrossBar, when the protective end-cap had come off, was reported. We advise pilots to inspect the Keel where the CrossBar sets above it, to ensure there is no metal-to-metal contact that results if the protective end-caps of the CrossBar become dislodged, for whatever reason.The caps are glued on for safety, but excessive heat or any object forced against the cap may move it from position. We recommend Keel tube replacement for any abrasions that are 0.020 deep, if this occurs. |

|

|

Advisory #: SA-107 Part: Sail - Rear Keel Pocket Strap Number of Incidents: 1 NOTE: If your webbing has excessive damage, then the webbing should be changed. This will require the sail to be removed and repaired. Please Check your rear Keel Pocket strap for wear at the tang. We think this was partly caused by the tang not able to move a little. You should be able to move the tang by hand fairly easy. If the tang is too tight, the webbing may move to the outside and the slot corner could start fraying the webbing. The other cause can be the plastic protector inside the tang slot simply cut through, and now the webbing has direct contact to the tang edge. FIX: We have a new protector on the tang now. We use a tube to make a better, rounded area that the webbing goes around. To update your tang we can send you the piece of tube for no charge, or you can order a complete tang with the tube installed. Rear Keel Pocket Strap Tang Order Code: AU36AA $4.93  |

|

|

Advisory #: SA-108 Part: none Number of Incidents: 1 Please Check your vent lines that runs down to the lower back frame. NOTE: If the vent line runs between the fuel tank and the frame, it has a chance to be compressed and closed. The tank slides back a little, and then expands enough when full of fuel to pinch the hose closed. If this happens, the vent closes and fuel can no longer go into the carburetor bowl. Solution: Move the vent lines to the outside (rear) of the back frame. Zip-tie it loosely to the support tube. Do not let the hose go below the airframe into the air stream either, as this causes a siphon to happen when the fast air goes by the end of the hose and will drain your fuel bowl. |

|

|

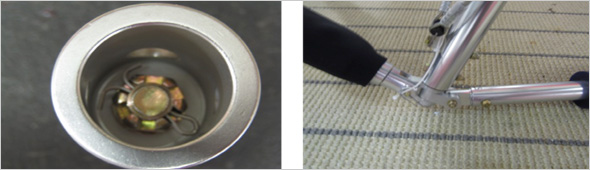

Advisory #: SA-109 Part: Strut Rotation Fitting Number of Incidents: 1 This advisory is to check the fittings on Maverick and Solairus wings from 2018 to 2020. We had one report of one wing that had no cotter pins. However we advise all wings to be checked from 2007 to current. Ground your wing until you have checked this!! Click here to print Service Advisory 109  There were two types of fittings (short and long). The short ones go up inside the strut and you cannot see the cotter pin through the pin install hole. So you must take the fitting out of the strut. The long fitting used on two place wings (2014 forward) you can see the 3/8" install hole and you can see the cotter pin through the holes. Short fitting: take out of the strut to check for cotter pin install.  Cotter Pin inside   |

|

|

This service advisory applies to Ultralight Aircraft only, not Light Sport Aircraft Attention: All MZ 34 Owners (installed on a North Wing product or any other manufacturer) There has been an incident where at least one Drive Pulley Plate bolt has loosened, and caused enough play in the drive to sheer the other two bolts off. This resulted in the whole re-drive assembly separating from the engine (propeller and all). We advise ALL MZ34 Owners (not only North Wing trikes) to check their bolts for proper torque. Taking the bolts out and re-torque them with red LocTite may be the best choice, if you see that any of the bolts have become loose. |

|

|

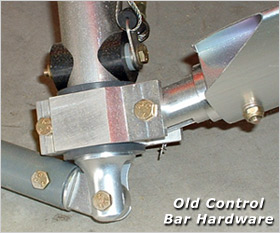

Where: Lower control bar (see picture) When: While using the folding wing ability. Problem: Fitting is sticking while rotating causing internal strut fitting to crack strut. If you are using the folding wing ability of your North Wing MPulse or Quest wing that has the fittings shown here, we suggest you upgrade to our newest control bar hardware. If you are not using the folding ability of your wing, you have nothing to be concerned about and changing the hardware is not necessary. If you have been using the fold back ability and are not sure if you have a problem with your fittings, then you likely do not have a problem. It will be very obvious that your strut is cracked (see picture). For those of you that need to change over to the new hardware, we will supply you with a whole retro kit for cost.  Contact North Wing by phone (509.682.4359) or email us to order this upgrade. Order Code - RTK16AD Control Bar Hardware Retrofit Kit   |

|

| NOTE: North Wing does not publish engine-specific Service Bulletins on this website. Please visit the following engine websites to view their service advisory information. |

|

|

Rotax Aircraft Engines - company website |

|

Rotax Owner Assistance Network - information and support |

|

HKS Aircraft Engines - company website |

|

Simonini Aircraft Engines - company website |

|

Compact Radial Engines (MZ 34) - company website |